How to Try New Media – Silicone Casting pt 4

- At June 07, 2013

- By sunhawk

- In How To - Guides

0

0

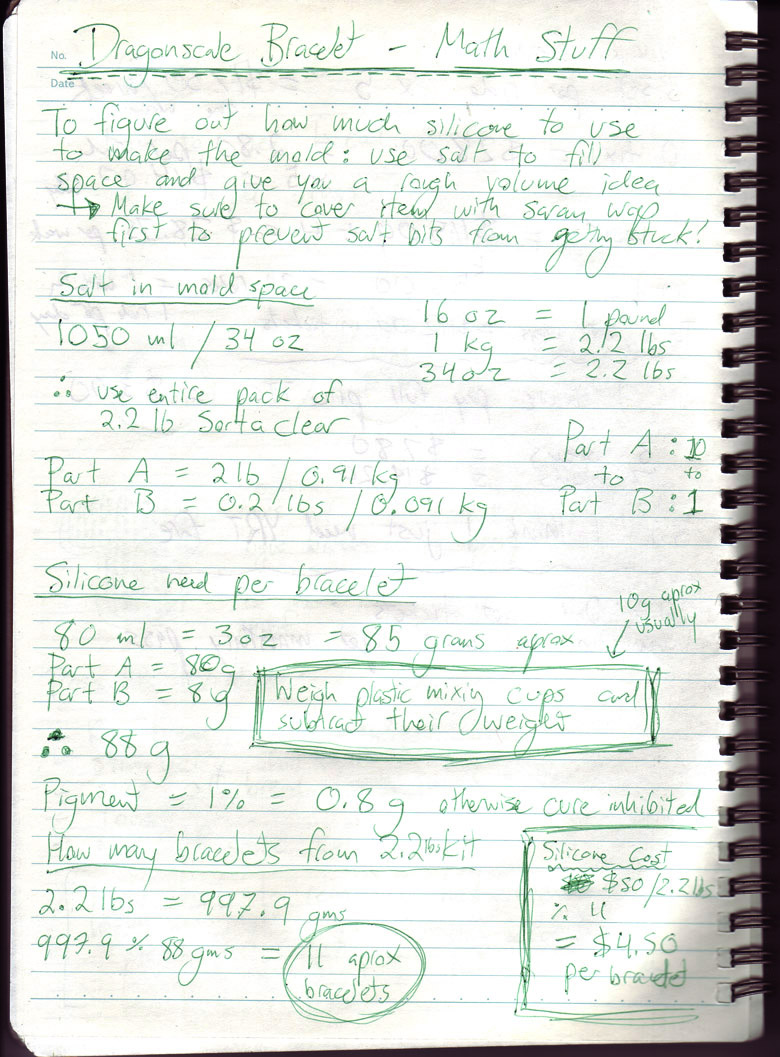

So now that I had my mold all ready to go, the last thing to do before using it was to figure out how much silicone I would need for each bracelet. This time I wanted a slightly more accurate number, because I would be using far less silicone and thus far less catalyst, so if I was off in my numbers it would have a greater chance of impacting whether the bracelet would cure or not.

6. Figuring Out Numbers and Setting Up Workspaces

I took my new silicone mold into the kitchen again and grabbed my teaspoon; this time I would be using water to figure out the volume dimensions, which would then give me number that I could use to figure out how much silicone I would need by weight. This is a tad tricky, because obviously water does not have the same density as silicone, which is why we don’t treat volume and weight as interchangeable, but for the purposes of getting close enough to allow me to mix up the silicone with only a little bit extra, my method worked well enough. The ratio of silicone to catalyst was 10:1 so as long as I kept strict with that, having a few extra grams of silicone in my mixing container would be considered an acceptable amount of waste.

Basically I filled up my mold with water one teaspoon at a time until the water reached the top of the mold space and kept track of the overall number of millilitres, as one teaspoon is roughly equal to five millilitres. As you can see in my notes above, the mold needed 85 grams to fill it up, and to keep things simple I rounded that number up a bit so that I would use 80 grams of silicone and 8 grams of catalyst, which would give me 88 grams total, which is not too shabby for waste.

With the math figured out, I next set out to set up the workspace I would be using to mix and pour the liquid silicone into the mold. I chose a room in my basement, both because our basement is unfinished and thus I can make a bit of a mess down there, and also the basement has the coolest rooms in the house, which would mean a slower setting time for the silicone which would give me a longer working time to mix and pour. I set up an old card table with a plastic tarp over it and laid out the various tools I had assembled, again I had extra bits and different options for mixing as I wasn’t sure which would prove most effective and helpful, so I had them on hand ready to go so I wouldn’t end up scrambling around while I had silicone and catalyst together waiting to turn into a solid.

- Item list, see below

- More safety first!

Items on the table include: 1. Electric thermometer, so I could see the room temperature 2. Mold release spray 3. Tub of silicone 4. Silicone catalyst 5. UV pigment (invisible in normal light, glows purple under blacklight/UV light) 6. Regular silicone color pignments and UV-reactive colour silicone pigments 7. Measuring cup 8. Plastic cups (they are hard to see in this pic) 9. Paintbrush from dollar store 10. Stir sticks meant for house paint 11. A kitchen hand-pumped vacuum chamber meant for degassing food 12. Eyedroppers, syringes without needles, cleaner brush 13. My silicone bracelet mold 14. Electric food scale

A good chunk of these tools ended up being unnecessary or unsuitable for the task at hand. The vacuumn chamber was something I wanted to try out, to see if it could act like a very small degassing chamber, but as far as I could tell it didn’t make any difference to the bubbles in the silicone. Even though it didn’t work, it still taught me something about silicone, which is always helpful.

Ironically, the tool I ended up using for mixing the silicone isn’t featured here, because I didn’t think of it until I started mixing the silicone. I measured out my silicone and catalyst using two plastic cups and the food scale, which was very handy as it has a setting to cancel out the weight of the plastic cup and thus give me very accurate results. Before I did any mixing, I first sprayed the mold with a mold release spray to ensure the braclet would pop out cleanly – something that isn’t necessary with a silcone mold UNLESS you are using it to cast more silicone, as silicone doesn’t stick to most other materials but it does stick to itself very well, which is something I didn’t know so it was good that I was told about it!

Part One: Pick A Project

Part Two: Organize Your Steps

Part Three: Safety First!

Part Four: Getting the Details Right

Part Five: Try Things Out and Evaluate

~Sunhawk

Get Social